From the design phases, production in our factories and on-site implementation, to assistance with operation and maintenance, POMA creates tailor-made solutions on an industrial scale with a view to the long term.

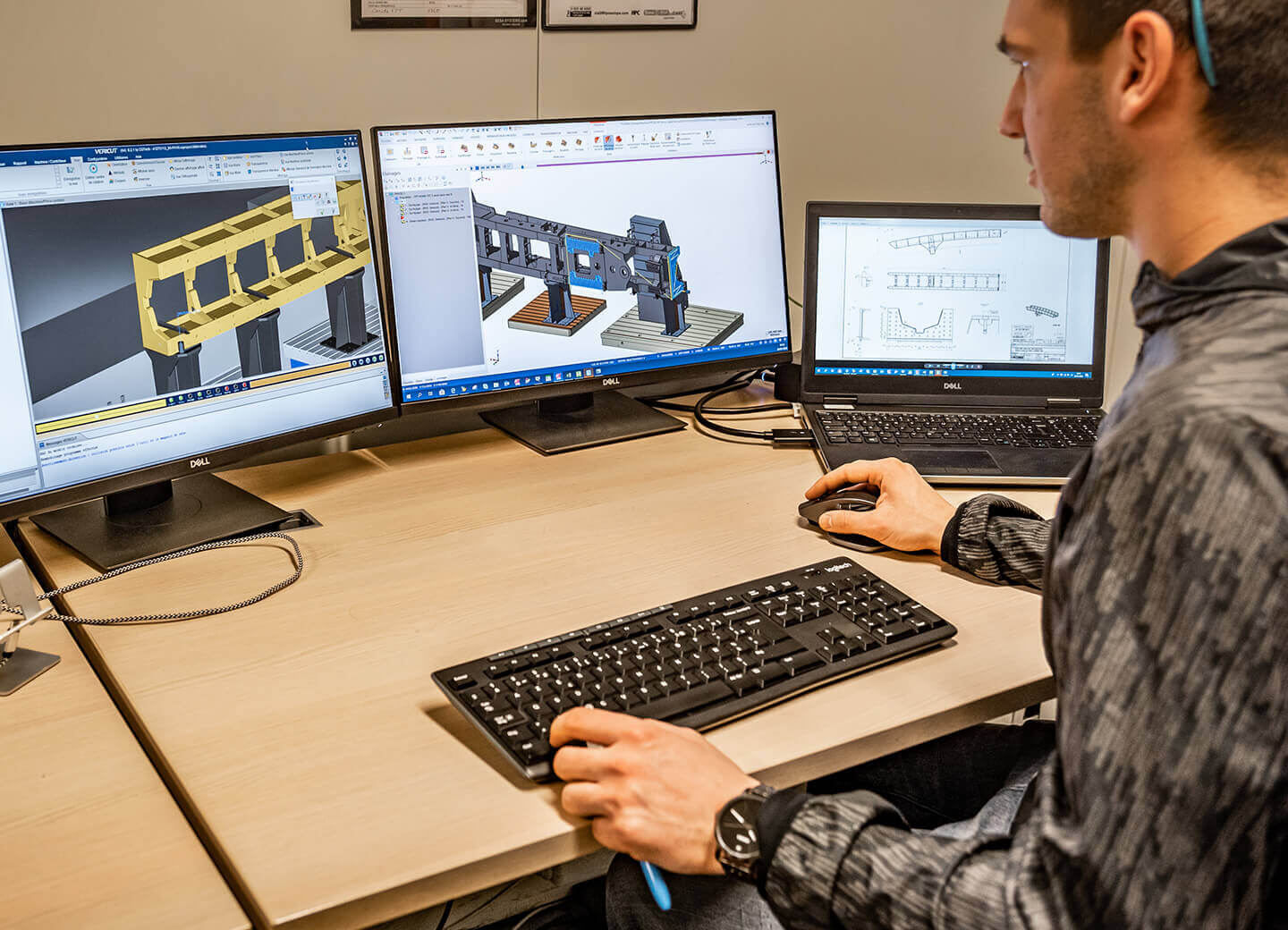

Engineering, operations, manufacturing, fitting, installation, etc., the organisation of the various units of expertise is supported by high levels of technical expertise, particularly on products with high added value, through both the means of production and the qualification of teams.

Systems engineers, project managers, automation technicians, maintenance personnel, expert fitters, site supervisors, technical support managers, industrial paint technicians, order pickers, quality assurance technicians, etc. The specificity of our profession requires specific skills, delivered by the expert and passionate men and women who make up POMA's teams. In order to respond to increased activity while retaining its business expertise in house, POMA builds upon on these advanced skills, continues to train its teams and recruit talent to generate the innovative processes of tomorrow.

Within the production entities in particular, POMA employees possess a wealth of knowledge: engineering, mechanical welding and machining of large structures form part of this. Discover our various production entities and units of expertise.

Discover our industrial sites and commercial subsidiaries