Innovation

POMA INNOVATION

POMA’s mobility offering is capacitive, low-carbon, accessible to all and comfortable. POMA innovates to create increasingly effective transport connections with a regular, controlled journey time, avoidance of natural and artificial obstacles, integration in all environments with a minimum footprint and an incomparable implementation speed.

for innovative, effective products

POMA’s has been a pioneer since the Group was created when, in 1936, Jean Pomagalski designed and produced the first detachable surface lifts.

This major innovation contributed to a boom in skiing and paved the way for a new market. Many other innovations were to follow, fine-tuning the technology and promoting the reputation of ropeway transport all over the world.

The POMA Group has won various innovation awards, and we file and protect several patents and brands every year in France.

For and in collaboration with our customers, POMA sees Research & Development as a driver for our business, based on feedback we have harnessed for decades.

Our goal: sustainable performance and comfort for users and operators

AN ECOSYSTEM OF INNOVATION AND CREATIVITY

A TEAM

OF 60 ENGINEERS AND Skilled EMPLOYEES

INVESTMENT

MORE THAN €6M INVESTED EVERY YEAR

6 PRODUCT & SERVICE INNOVATIONS

ON AVERAGE EVERY YEAR

OVER 120

ACTIVE PATENTS THROUGHOUT THE WORLD

PARTNERSHIPS WORLDWIDE

STARTUPS, SCHOOLS AND UNIVERSITIES, PUBLIC AND PRIVATE LABORATORIES

dedicated to innovation

From the very first detachable surface lift to the latest cutting-edge technologies, innovation is part of POMA’s identity. Our teams are constantly working to improve our products, services and processes.

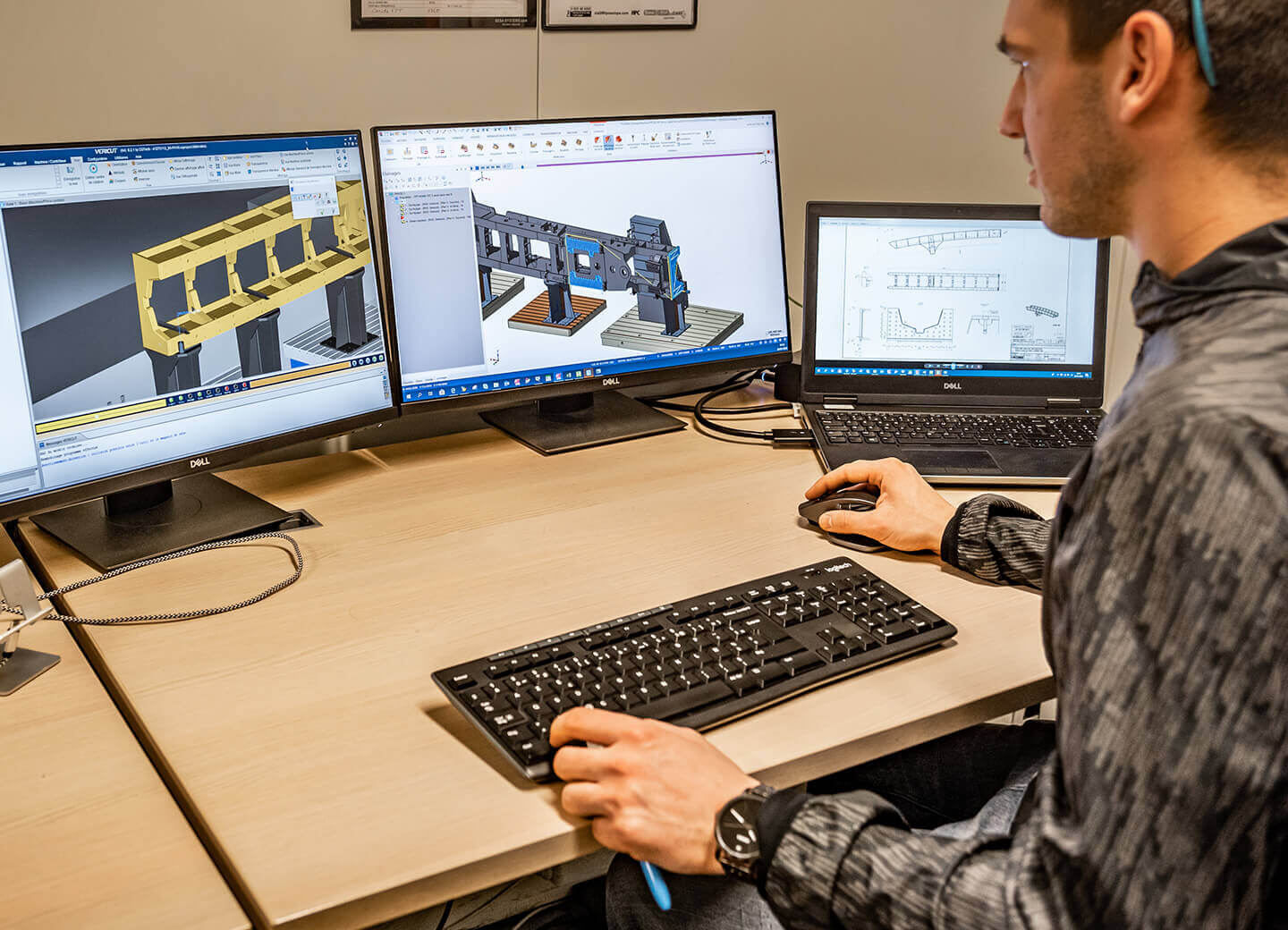

At POMA, innovation is shared between and supported in all Group business units and subsidiaries. Within the Group, around sixty people with a wide range of skills work in Research & Development. The men and women in this multidisciplinary and motivated team really make it what it is. They all master the challenges of the various business areas involved in ropeway transport, in particular by regularly working in the field and being attentive to operators, so as to support them on a daily basis.

From systems engineering to industrial design, automation professions to customised technical design and site preparation to town planning, not forgetting our experts on environmental issues, POMA is supported by a number of complementary professions and professionals from different backgrounds, who enhance our overall understanding of user and operator needs.

of Research & Development at POMA

Very early on in our value chain, POMA invests in optimising products and processes, based on a large amount of feedback, collected particularly in the field, in the most restricted environments and also via a technology watch extended to third-party business sectors, to harness technology trends and adapt them to ropeway transport technology.

POMA, specialised in engineering and manufacturing since 1936, has extended its scope of expertise for its ropeway transport customers by also becoming a service provider. The Group has for example recruited French experts in operations and maintenance, finance, research, etc. for comprehensive project support.

OUR MISSION: THE RIGHT INNOVATION

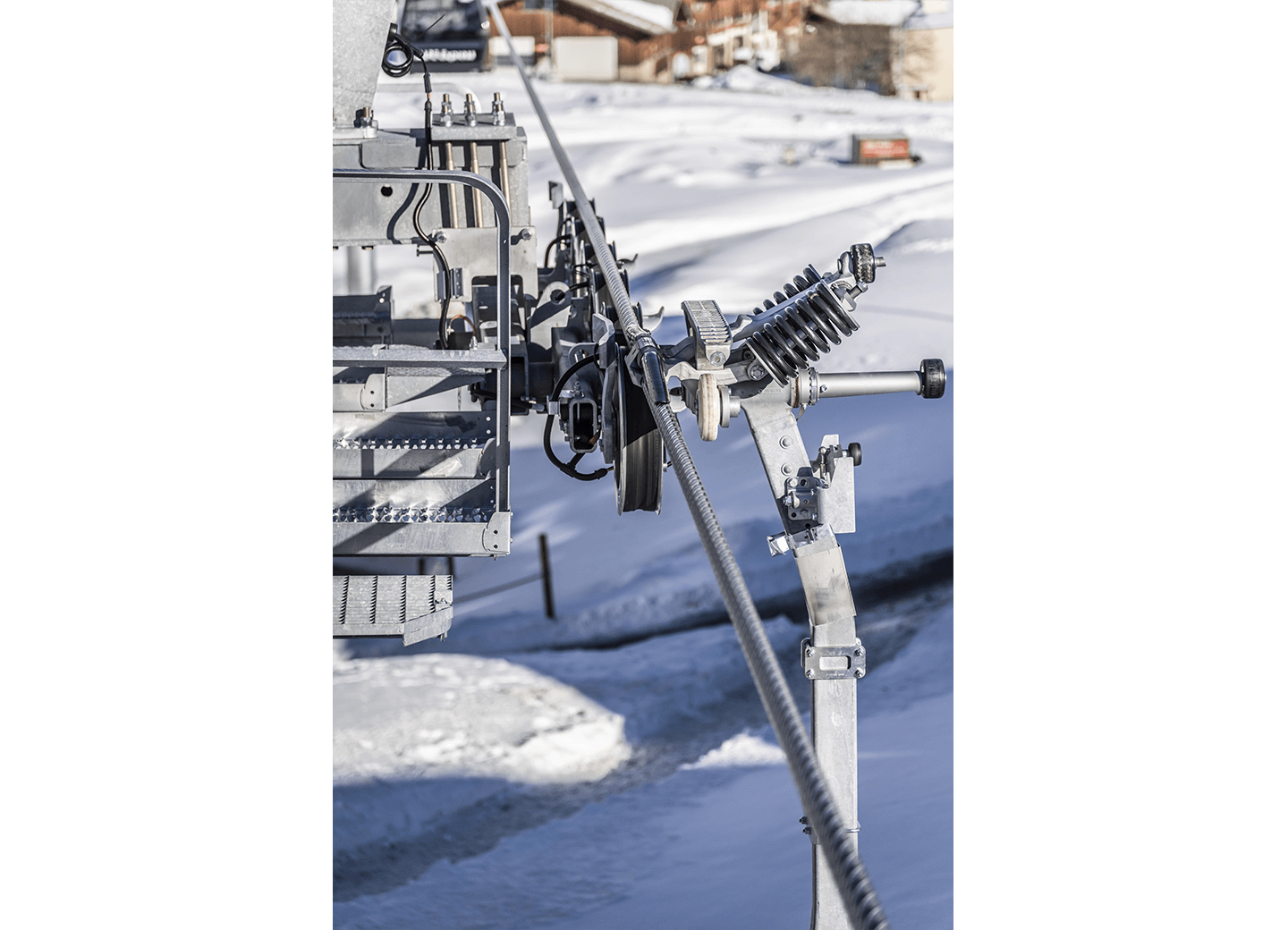

With motors, ropes, bearings, roller batteries, carriages, carriers, and so on, whether regarding breakthrough technological innovations or incremental changes, the system and all of its components undergo specific Research & Development.

System safety and availability are always our main focuses, within a holistic approach to eco-performance in which POMA strives to act by designing and selecting materials to optimise energy efficiency and offer ever more comfort.

OUR VISION: DESIGNING MOBILITY OF THE FUTURE

POMA focuses all of its efforts on Research & Development to make sure ropeway transport becomes a relevant, reliable, sustainable mobility solution, regardless of environment and use and independent of external factors. POMA technology is tried and tested and perfectly suited to regional macro-economic challenges, where mobility is key.

From initial discussions, all POMA R&D involves significant collaboration from customers and all other industry stakeholders, which provides new perspectives. At POMA we consider that collective intelligence enables us to be even more virtuous.

Products and services

Innovations for all

Whether for breakthrough or frugal innovations, POMA pursues a number of methods based on specific objectives, always with the aim of enabling the continuous improvement of our products and services. Amongst the topics that currently hold our attention are next-generation roller batteries and high-performance detachable grips.

From monocable to bicable (2S) and even tricable (3S) ropeways, POMA ropeway transport systems are effective and sustainable.

Although these technologies have very specific uses and system configurations, they all have a common structure, enabling a significant amount of innovation cross-over, such as the use of new energies and thermal management for passenger comfort.

It is therefore possible to use the same innovation for different products, resulting in a benefit for all customers and their fleets, in all areas of system performance: comfort, capacity, speed, silence and so on.

Continuous improvement of product & service performance

A PIONEER OF SUSTAINABLE MOBILITY

At POMA, innovation involves coming up with products of the future using sustainable designs that are environmentally friendly.

Almost 80% of the materials used are recyclable and the infrastructure can be easily reconfigured and disassembled. POMA is enhancing its position on the sustainable mobility market by using the skills gained in its various business areas and rolling them out for all customers.

This, in association with a robust eco-design approach, ensures that the carbon footprint of the ropeway transport solution remains very low.

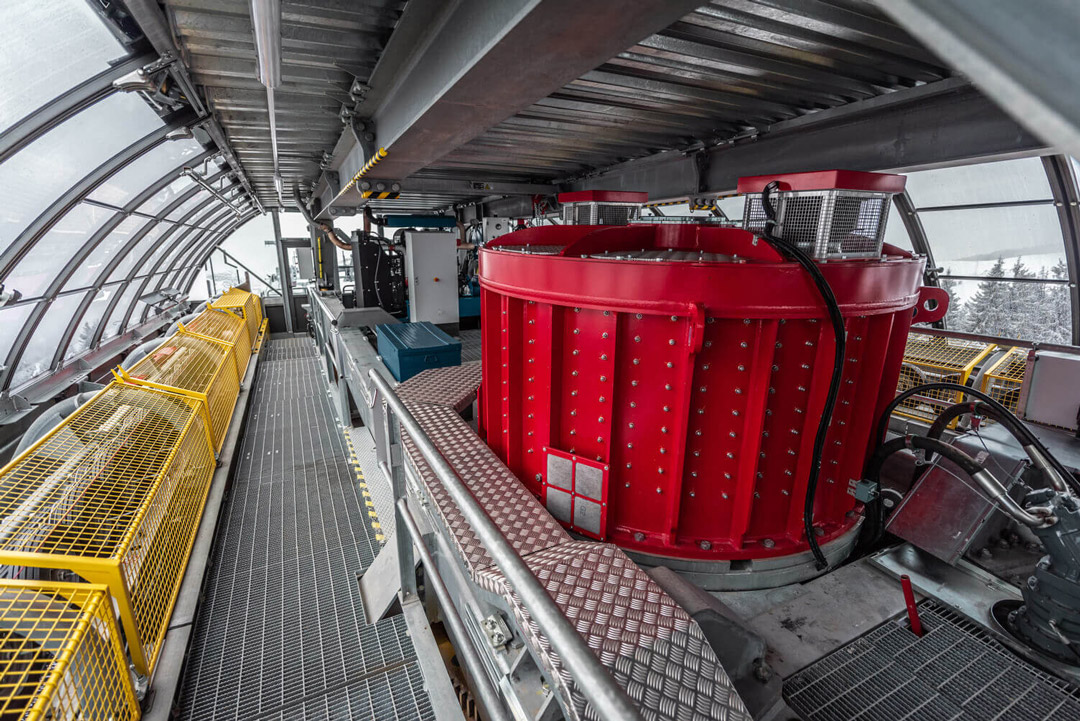

DIRECTDRIVE® MOTOR

DirectDrive® is the POMA technology used throughout the world, which, instead of a conventional drive train (gear motor), enables direct driving of the drive sheave without the need for an intermediate gearbox. DirectDrive® has three advantages that are part of a comprehensive eco-friendly approach: a significant decrease in energy consumption, no oil consumption and a substantial reduction in noise pollution.

Recently, the POMA R&D department developed the DirectDrive® offer, for an even quieter motor. Work on motor ventilation resulted in decreasing the noise level by 15 decibels. Energy consumption was also reduced by 8%, additionally providing the possibility to recover thermal units to supply a third-party space. With no hydrocarbons, oil or lubricant, this technology is a real advantage, both making us green and ensuring user well-being.

In five years, DirectDrive® has gone from 30 to 190 installations using this technology.

REDUCED ENERGY LOSSES

Ropeway transport systems have low electrical power consumption compared to other modes of public transport and are also able to generate this power. It is in fact possible to store energy when descending carriers transport more passengers than ascending carriers, then to reinsert the power back into the circuit when the opposite is true, or to auto-consume it directly by supplying connected or nearby electrical equipment.

Technical solutions, some of which have been subject to patents, have also been developed to reduce the power consumption of ropeway transport systems insofar as possible, for example via a specific positioning of the towers and optimised management of carrier spacing.

NEW SILENT CABLE

Just like the motors, rope entry into stations and on towers is increasingly silent. By relying on the best product experts internally and at rope manufacturers, POMA has been able to industrialise new “silent” ropes.

These ropes have plastic fins to fill the gaps between the strands, to move towards a perfectly cylindrical shape, thus limiting vibrations upon contact with sheaves and rollers. This solution also reduces wear and tear of tower and station components, therefore increasing their service life.

POMA’s use of this technology therefore helps reduce noise and maintenance costs.

From the French Alps to Latin America, this innovation appeals to our customers. In Medellín, silent ropes have been installed, firstly on line H in 2016, then in 2019 on the line. Our customers, who were the first to take interest in this innovation, have mixed tourist/urban installations such as the gondola lift called the ALPE EXPRESS, a dedicated transport corridor installed in Alpe d’Huez in 2018, or the gondola lift from Le Praz to Courchevel installed in 2019.

SOURCES OF ALTERNATIVE ENERGY

Complementary sources of energy may be built into the cabins to supply some of their options, and now on the roofs of stations – solar power has become one of POMA’s industrial processes.

This principle meets the needs of operator-customers who are committed to producing green energy, such as the Serre-Chevalier resort for example, which has very good sun cover and is a forerunner in energy transition.

Since the law changed, enabling the use of current produced on site, wind power is also being studied by ski resorts as a green energy solution. POMA, convinced that this approach enhances virtuous action, is currently conducting tests to adapt capacities so they are as in line as possible with local consumption needs, deeming that use by all mountain stakeholders is possible.

More broadly, all POMA ropeway transport systems, regardless of use (leisure or commuting), can benefit from technological advances in integrating alternative energy sources.

ENERGY OPTIMISATION

The energy efficiency of an installation may be impacted by various factors: system configuration (position of towers and carriers), friction, shape and part design (e.g. carrier aerodynamics), motor technologies, station drive systems and the choice of ropes, and so on.

Operating conditions are also important. Depending on the day of the year, the time of day and level of occupancy, more virtuous driving methods can be implemented. Artificial intelligence and big data are used to analyse a large amount of information on various systems and therefore help find the best configurations for new systems and the best operating methods for existing systems.

Although solutions already exist, POMA engineers continue to work on optimising products and calculations using this valuable data based on feedback, especially when POMA operates and maintains the systems.

LIMITING FRICTION

One of the main challenges in POMA’s line of business is to reduce friction for improved noise comfort, lower energy consumption and a longer service life. Thanks to its experience in cities, where ropeways are operated up to six times more than in a winter sports resort (7,000 operating hours a year compared to 1,200 hours), POMA is innovating in the effective service life of parts.

As such, and closely linked to maintenance gains for operators, POMA innovates every year by developing components that are increasingly effective in limiting friction, which extends system capacity and makes ropeway transport one of the quietest modes of transport.

INTELLIGENCE FOR EFFICIENCY AND SUSTAINABILITY

The cutting-edge technology used and implemented by POMA helps manage the energy consumption of a ropeway. It has been possible for several years to install secure monitoring systems on existing or new ropeways to collect data, sometimes in real time, so as to find the best operating methods to reduce energy consumption and adapt driving.

The “ECO CONDUITE” tool developed by POMA demonstrates this: using passenger flow analysis amongst other parameters, operators can choose amongst other things to adapt carrier speed, reducing it in off-peak times, for example.

SMARTBOARD, THE NEXT-GENERATION DRIVER’S STATION

The new SmartBOARD design enables integration below the bay window of the operators’ room, to easily view the areas to be monitored whilst optimising available space. The control system is simplified, as is traffic on the information screen. The two operating touch-screens pivot 180° and so can even be used from outside. The first screen, dedicated to ropeway operation, accommodates the driver’s station interface, the operating modes, all parameter statuses and the component variables of the ropeway (by location or function). Amongst other things, it offers access to pre-recorded tests from routine checks, the ZenIS load simulator and the EcoDRIVE mode.

The second screen is dedicated to the functions for operating and maintenance aids. In particular, by keeping data fully secure, it enables the use of advanced features from the COPILOT and HyperView software or the TimeLINE mode.

INNOVATION FOR OPERATION AND MAINTENANCE

For its customers in France and abroad, POMA innovates by setting up operation and maintenance aid services to guarantee the safety and availability of their systems every day of the year. U

sing experience gained over decades of operations, when requested by the customer, POMA recruits, trains and provides a team fully dedicated to system maintenance.

To satisfy increasing demand, POMA has created a new service offering based on maintenance engineering. Maintenance monitoring analysis is used to accurately design the best maintenance policy for the systems: preventive maintenance, condition-based maintenance with vibratory analysis systems, the drafting of maintenance plans to suit the profile of the systems and data to provide information to the Computerised Maintenance Management System (CMMS) software.

Although various monitoring systems are already available, in the long term, on-board intelligence for the systems will enable them to be monitored throughout their service life. In addition to enhanced product expertise, feedback paves the way for predictive maintenance for each ropeway, using data on part wear and tear and use. Planning for and preventing failures is a major challenge for operators, and providing the possibility to limit expenditure on heavy maintenance is a strong financial argument.

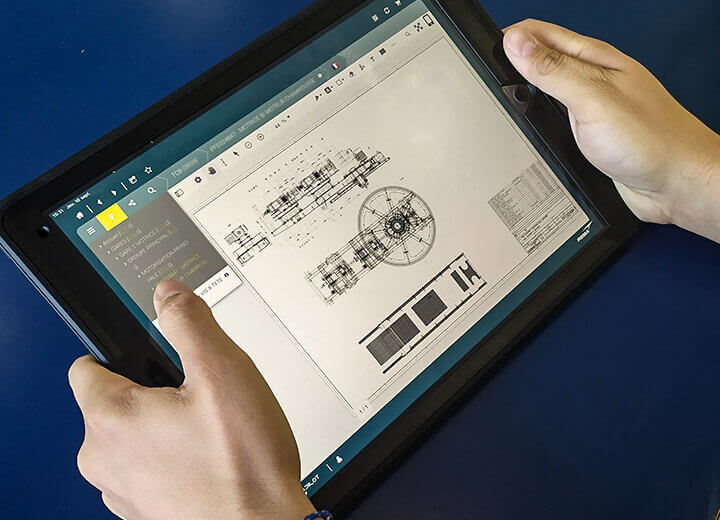

DIGITAL SOLUTIONS FOR ALL-ROUND SUPPORT

An engineering and manufacturing company since 1936, POMA has extended its scope of expertise for its ropeway transport customers by also becoming a service provider, to support customers in ropeway transport system operations and maintenance. The Group uses French digital experts in particular.

POMA has developed two digital tools specifically for ropeway transport system operators: UPILOT® and COPILOT. These fully meet all operator, maintenance team and future ropeway driver expectations.

POMA is innovative and is enhancing its capacity to support ropeway transport system operators with two tools that are now vital in the transfer of skills and technical support for customers, to operate their systems safely and guarantee availability.

of research and development

Targeted, pragmatic innovation: Data monitoring and recovery

The technical and technological performance of our systems is based on continuous innovation.

Producing a cabin for passengers in Galala (Egypt) with temperatures of 40°C is different to producing one for Veduchi (Russia) with temperatures of -15°C. For POMA, knowing how systems and equipment operate regardless of conditions is the key to determining what is really necessary, based on systems installed throughout the world, to gather data on use in all climates, making our innovations real responses to actual needs.

POMA products are subject to continuous innovation so they can be successfully integrated in an urban setting, comply with environmental requirements and be suitable for increasingly complex topographies. Performance assessments are also carried out throughout system service life to enhance POMA expertise.

Thus, decades of data, information and feedback gained from all over the world and in all applications of ropeway transport enable POMA to conduct the most relevant R&D projects for its customers. Understanding the challenges and capacities to implement them results in optimised solutions to support customers in daily operations, with assessed environmental parameters.

POMA has always been a pioneer in mobility. Today, calculation software, physical test benches, digital twins, 3D printers and other cutting-edge tools enable the R&D teams to conduct projects until the prototype is confirmed and the product is tried and tested. Few stakeholders in ropeway transport can say as much, which helps set us apart as a leader.

Knowing who to be around

Industrialisation is only possible via innovation and collaborative experiments. Therefore, in the design process for new products, POMA integrates several pivotal stakeholders with, above all, active collaboration with operator-customers, who are an essential link in the development of products.

Pivotal customers work alongside POMA for more safety, availability and comfort for all. POMA is also surrounded by professionals in cybersecurity for the digital solutions provided, and experts in all other areas where necessary.

Internally, our project teams work using a method that pools and optimises Group expertise. Cross-cutting skills are included in the discussion process to provide more opinions on the concept and come up with a better solution from a collective point of view.

At industry level, POMA is recognised as a major stakeholder in ropeway mobility. Due to this, real, solid partnerships have become possible, so as to meet current needs in global urban transport when it comes to sustainable mobility. This, for example, requires strategic cooperation in R&D for the urban mobility of the future, alongside transport groups and engineering firms or Smart City stakeholders.

On a regular basis, POMA teams are involved in collaborative projects alongside major French companies, such as the following projects: Astainable (with EIFFAGE, ENGIE and EGIS), Phosphore (with EIFFAGE and DASSAULT SYSTEME), and I2TC (with EIFFAGE and RATP).

POMA is therefore present in areas that are designing the mobility of the future, helping them benefit from the latest innovations and deliver the service as quickly as possible to all Group customers.

The POMA advantage

A global link: this is how we envisage our use of internal and external POMA resources. The approach we take requires collaboration with the local ecosystem. Private stakeholders, start-ups and large groups and academics throughout the world rely on us at our local sites to develop partnerships with local stakeholders. POMA searches for skilled resources as near as possible to these stakeholders.

Technical mastery of the product

With over 80 years of experience, our technology has been tried and tested throughout the world, which enables continuous innovation that really meets customer expectations.

Our solutions are designed for each customer need and almost become customised offers for optimal performance. This freedom is possible thanks to complete technical mastery of our products and to our committed teams.

By mastering the product, from design to maintenance, POMA is also a pioneer in designing tools and services that aim to strengthen the professional skills linked to ropeway transport. This is a virtuous approach that has proven its worth, allowing us to constantly achieve better safety and availability.

POMA innovation awarded.

HERMÈS INNOVATION AWARD

POMA received the Hermès innovation award in 2016 for the Improvement of Life in the City category from Marc Giget, CEO and Scientific Director of the Paris Innovation Directors Club and the European Institute for Creative Strategies & Innovation

This award for excellence recognises POMA innovations in improving city life by using urban ropeway transport.

of POMA’s innovation

- Amongst the POMA innovations, various products, services and processes handled by the R&D teams primarily offer concrete, observable results.

Our systems can be installed anywhere, regardless of environment and use and in any climate, and are supported by digital solutions that can be easily deployed.

Ours are tried and tested systems that are continually enhanced via new developments, so they are always better suited to the environments and issues specific to their operating contexts. - Standards and regulations:POMA, due to its role in the industry and its globally recognised expertise, helps draft regulations for ski lifts in several countries. As such, our teams can work with authorities and ministries to help them establish and develop regulations and standards on ropeway transport.

DISCOVER OUR OTHER EXPERTISE

POMA Service

POMA is your preferred partner throughout the life cycle of your ropeway transport system. It is our commitment to share your safety, availability and sustainability requirements. We are therefore present alongside your teams to put our know-how and expertise at your service every day.

Learn more

Technology

From mountains to cities, transporting tourists and materials, POMA is known worldwide for its skill in designing, making, operating and maintaining ropeway transport solutions. For decades, POMA’s technologies have been honouring the commitment to provide a comfortable, fast, energy-efficient, silent and non-polluting form of transport.

Learn more